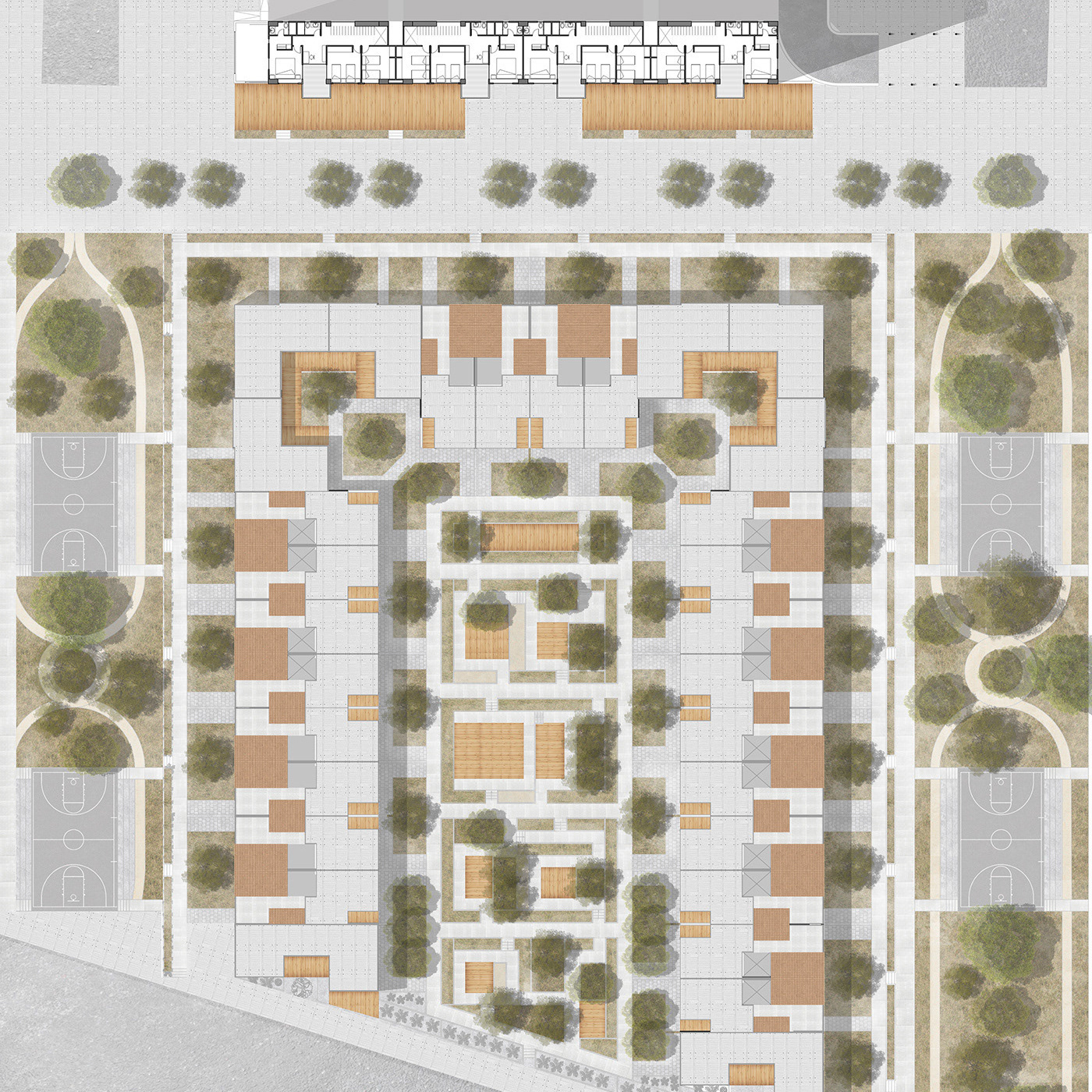

Product Optimization: Diamond Suite by The New Makers Company

As a vital member of The New Makers team, I spearheaded the product optimization efforts for the Pre-Fab Diamond Suite units' building process. My primary focus was on the meticulous study, assessment, and re-engineering of building components to enhance building assembly and in-house building capacity, achieved by incorporating advanced component + assembly systems through CNC technology.

Key Implementations:

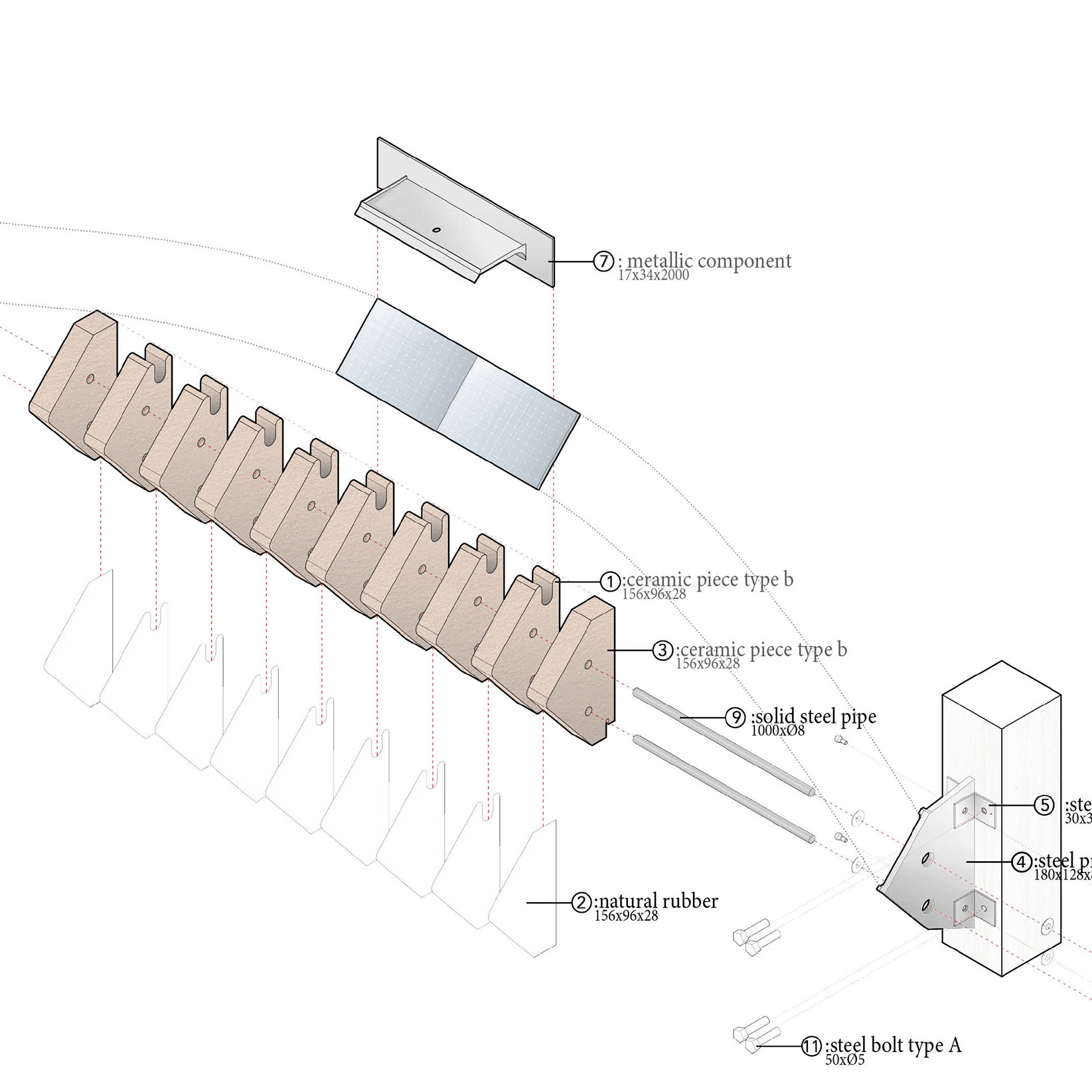

1. Modular Facades Wall for Multiple Fenestration Products (Prototype)

Developed a cutting-edge modular facades wall, accommodating various fenestration products to offer versatile architectural solutions.

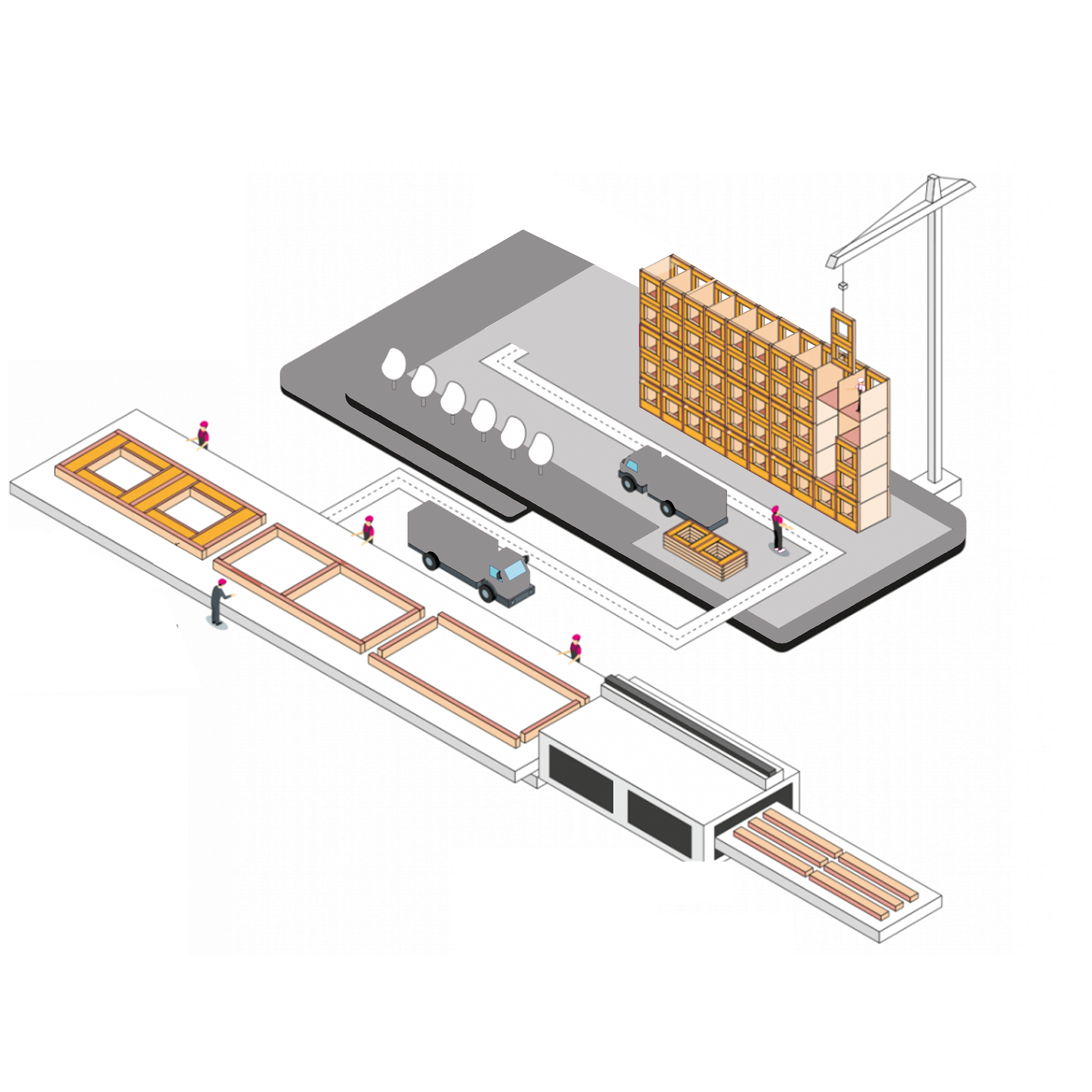

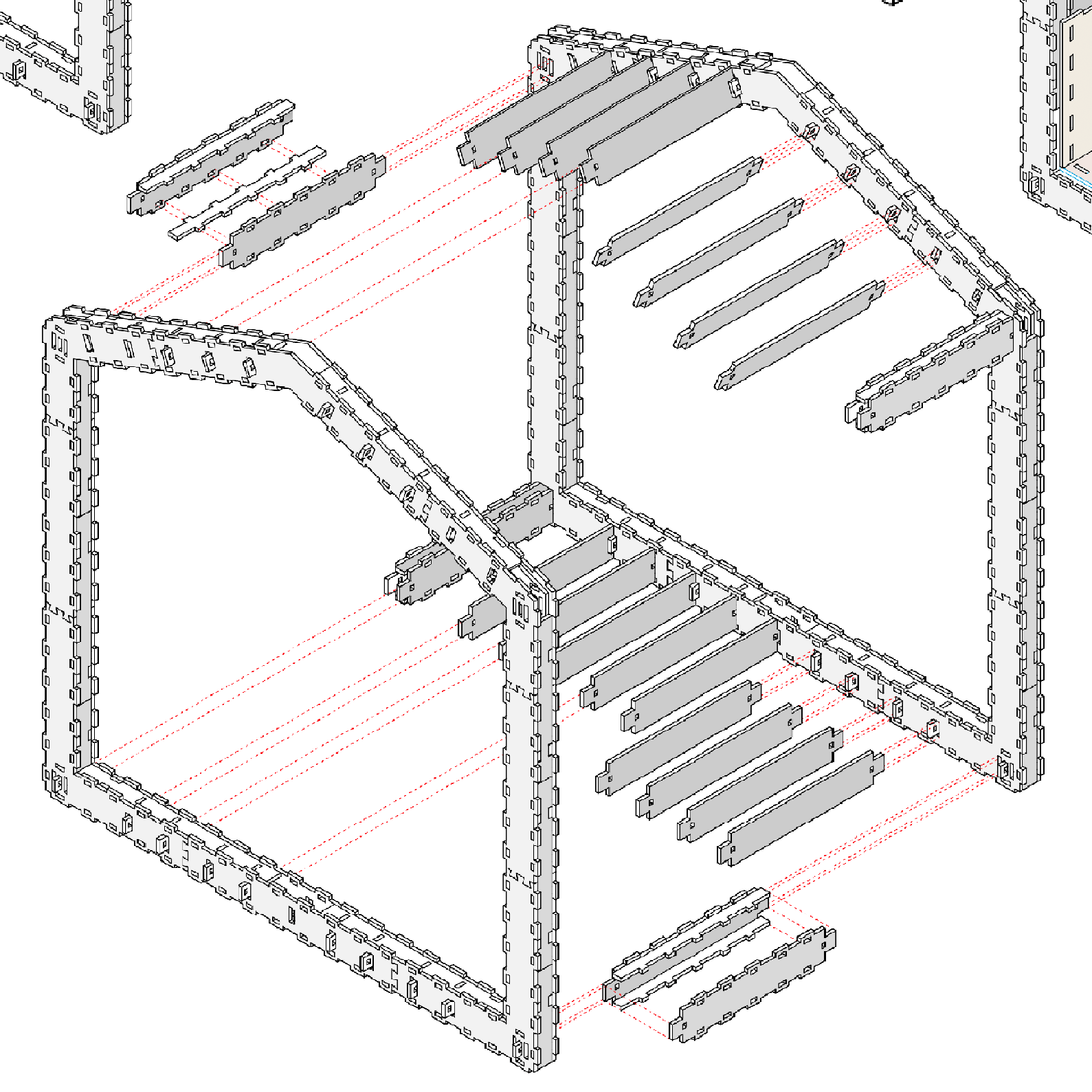

2. Pre-Fab Load-Bearing Wall System with Snap-In Joint Systems

Designed a pre-fabricated load-bearing wall system featuring innovative snap-in joint systems, ensuring rapid and efficient assembly.

3. Special Fenestration System Façade Component

Created a dedicated façade component to complement a unique fenestration system, enhancing the overall aesthetic and performance.

4. Interior Modular Furniture System

Introduced a flexible and adaptable interior modular furniture system, optimizing space utilization and enhancing user experience.

5. Automated Time Assessment Platform for CNC Fabrication/Nesting Optimization

Implemented an automated time assessment platform that streamlines CNC fabrication processes and optimizes nesting, reducing production time and costs.